Product analysis:

Heavy-duty polyethylene 2100, also known as L2100TN00, is a lightweight, film-grade low-density polyethylene (LDPE) known for its excellent flexibility, toughness, and processability. As a versatile polymer, it is widely used in industries requiring thin, flexible films, such as packaging and agriculture. This material provides the benefits of low density while maintaining durability, making it ideal for various applications. However, it is important to note that Low-Density Polyethylene 2100 is not intended for and must not be used in any pharmaceutical or medical applications, as it is not suitable for such uses.

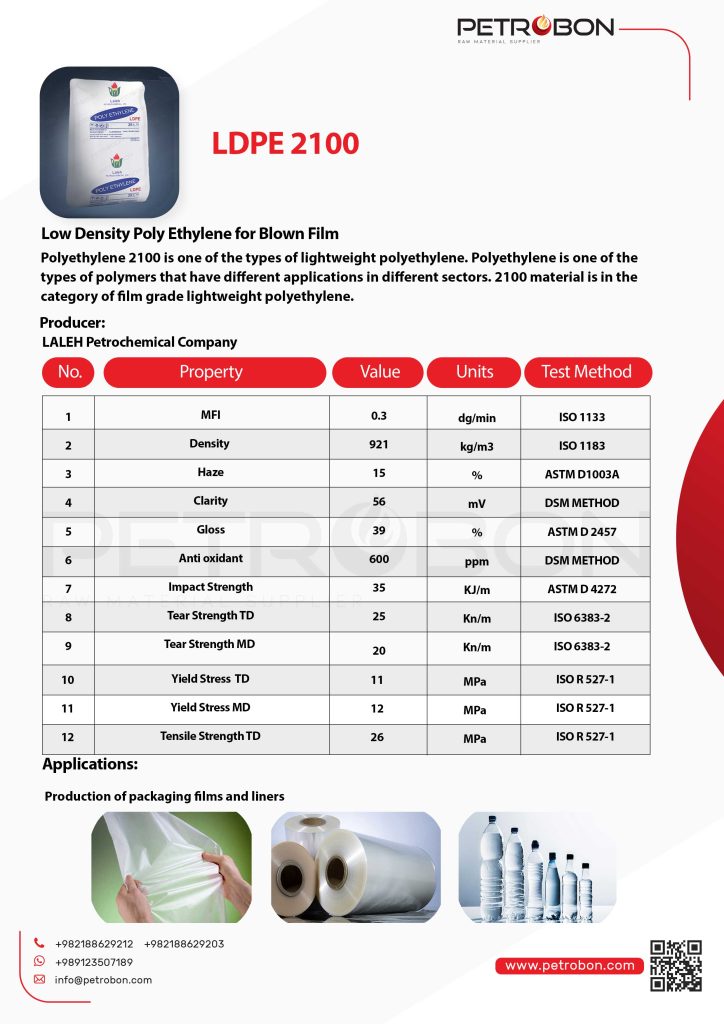

It features a density of 0.921 (g/cm³) and an MFI of 0.3 (190 °C/2.16 Kg). This grade is supplied in granular (pellet) form and contains no additives. PE 2100 is manufactured by Laleh Petrochemical Company under HS code 39011030.

- High durability

It refers to the material’s ability to withstand wear, pressure, and damage over time. This means that PE LDPE2100 maintains its structural integrity and performance even in demanding conditions, making it reliable for long-term use in various applications.

- Excellent draw-down ability

This property indicates the material’s capacity to be stretched or thinned during processing without breaking. This property is crucial in film production, allowing for the creation of very thin yet strong films, maximizing material efficiency, and reducing waste.

- Excellent toughness and tear strength

This attribute highlights the material’s resistance to cracking and tearing under stress. Polyethylene 2100 combines flexibility with strength, ensuring that it can endure physical impacts and tension without failing, making it ideal for applications requiring resilience.

- Outstanding shrink property

It refers to the material’s ability to shrink tightly when exposed to heat. This is particularly important in packaging applications, where a snug fit around products is required, providing a secure, protective covering that adapts to the product’s shape.

- Good processability

It means the material is easy to work with during manufacturing. It can be molded, extruded, or formed into various shapes and films with minimal difficulty, ensuring consistent quality and efficiency in production processes.

- Good optical properties

It represents the material’s clarity and transparency, allowing for clear visibility of the contents within the packaging. This attribute is particularly important in retail and food packaging, where the appearance of the product is crucial for consumer appeal and presentation.

- Low odor and taste

Low odor and taste indicate that the material does not impart any noticeable smell or flavor to the products it comes into contact with. This is essential in food packaging, as it ensures that the packaged food remains unaltered in flavor and aroma, maintaining its original quality.

- Low migration levels

That means that the material has a minimal tendency to transfer substances to the products it contacts, especially food. This attribute is critical in food packaging, ensuring that harmful chemicals or additives do not leach into the food, thus safeguarding consumer health and product safety.

LDPE L2100TN00 is widely used in producing packaging films and liners for demanding applications. Its excellent shrink properties and toughness make it ideal for shrink hoods, which are used to wrap pallets or bundles of goods securely. This ensures stability during transportation and storage, protecting products from damage. Additionally, the high tear strength and exceptional draw-down ability of LD 2100 allow for the creation of thin yet strong films, making it perfect for industrial sacks. These heavy-duty bags can carry large quantities of materials without tearing, even under rough handling conditions.

In the food packaging and retail sectors,2100TN is also a preferred material for manufacturing carrier bags and liners. Its good optical properties, combined with low odor and taste, make it ideal for food packaging, maintaining the freshness and integrity of the contents. The clarity and aesthetic appeal of the material enhances its suitability for retail bags, where visual appeal is important. Moreover, the low migration levels of this polyethylene make it safe for food applications, ensuring consumer safety while providing durable and attractive packaging solutions.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for LDPE 2100 may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for LDPE 2100. Please contact us to inquire about the daily prices. You can also find price changes of this material in the chart provided in this section.

Product analysis:

Laleh Petrochemical PE LDPE2100

You can see the technical specifications of PE LDPE2100 | PE LDPE2100 in the following datasheet.