Product analysis:

HDPE EX3 is also known as GM 5010 T2N. It is a high molecular weight, high-density polyethylene copolymer, developed as a general-purpose resin used in pressure and non-pressure pipes. HM 5010 T2N is a bimodal high-density polyethylene with 1-butene as a comonomer. Polyethylene EX3, a PE80 class copolymer, is a colorless, heavy-duty material capable of withstanding prolonged internal pressures at elevated temperatures. This pipe-grade resin is manufactured by suspension polymerization of ethylene monomer.

A minimum service life of 50 years is achievable under appropriate pressure and temperature conditions, making it highly reliable for long-term applications.

f00851 features 0.955 (g/cm³) density and 12 (190 °C/21.6 Kg) MFI. This grade is supplied in the shape of transparent granules (pellets) and includes antioxidants to stabilize the polymer during processing and usage, and UV stabilizers to enhance UV resistance. Jam, Marun, and Amir Kabir Petrochemical Companies manufacture GM 5010 T2N under HS code 39012090.

- High impact resistance

This feature represents the material’s ability to resist shock or impact without breaking or cracking. Products made from this polyethylene can withstand hits or pressures. They have flexibility and toughness. These products can last longer and perform well in a wide variety of applications.

- Extraordinary hydrostatic resistance

It is related to the ability of the materials to withstand internal pressures from fluids or gasses over extended periods without rupturing or deforming significantly. This polyethylene is preferred for pipe applications over metals. They don’t rust and because of flexibility can accommodate some ground movement.

- Good ESCR

ESCR stands for environmental stress crack resistance. It explains the ability of a material to resist cracking under stress and exposure to certain environments. Great ESCR means this polyethylene provides durability and longevity in harsh conditions.

- Excellent chemical resistance

This polyethylene demonstrates excellent resistance to a wide range of chemicals without significant physical changes. In chemically challenging environments, it can help ensure safety and longevity for various productions.

EX3 is engineered for high-performance applications in pipe and fittings sizes where high-density resins are required. It provides durability, reliability, and versatility. By use of stabilizers and pigments, this grade is applied for piping under UV radiation in gas and liquid transportation and a broad range of industries in rural, and mining applications. It is also certified for food contact, ensuring safety and compliance with health regulations.

Petrobon is supplying this material to various cities in different countries. Therefore, the logistics process and cost for SABIC-f00851 may vary. Contact our professional team for detailed information and guidance, based on your location and requirements.

There is a fact that global oil prices are variable. That means there is no stable and specific price for GM 5010 T2N. Please contact us to inquire about the daily prices. You can also find the price changes of this material in the chart provided in this section.

Product analysis:

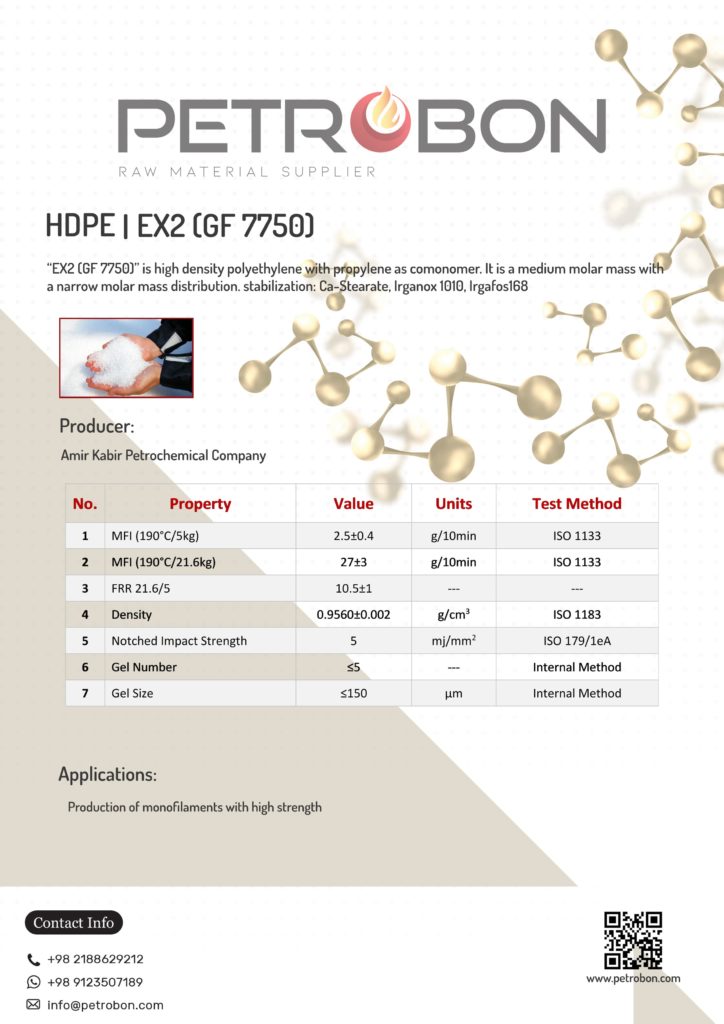

Amir Kabir Petrochemical EX2

(GF 7750)

You can see the technical specifications of HDPE EX2 | PE GF 7750 in the following datasheet.