Product analysis:

GPPS 1540 Crystal Polystyrene is a high-performance material tailored for extrusion and injection molding applications. It can be seen as General Purpose Polystyrene Injection 1540 or General Purpose Polystyrene Extrusion 1540. It is known for its excellent fluidity and elevated softening point compared to GPPS 1810/1811. It significantly improves extruder output and reduces thermoforming cycle times, especially when combined with super high-impact polystyrene like HIPS 7240. This grade is particularly effective for glossy-layer co-extrusion processes, making it a preferred choice for applications that require both enhanced thermal resistance and a high-quality surface finish.

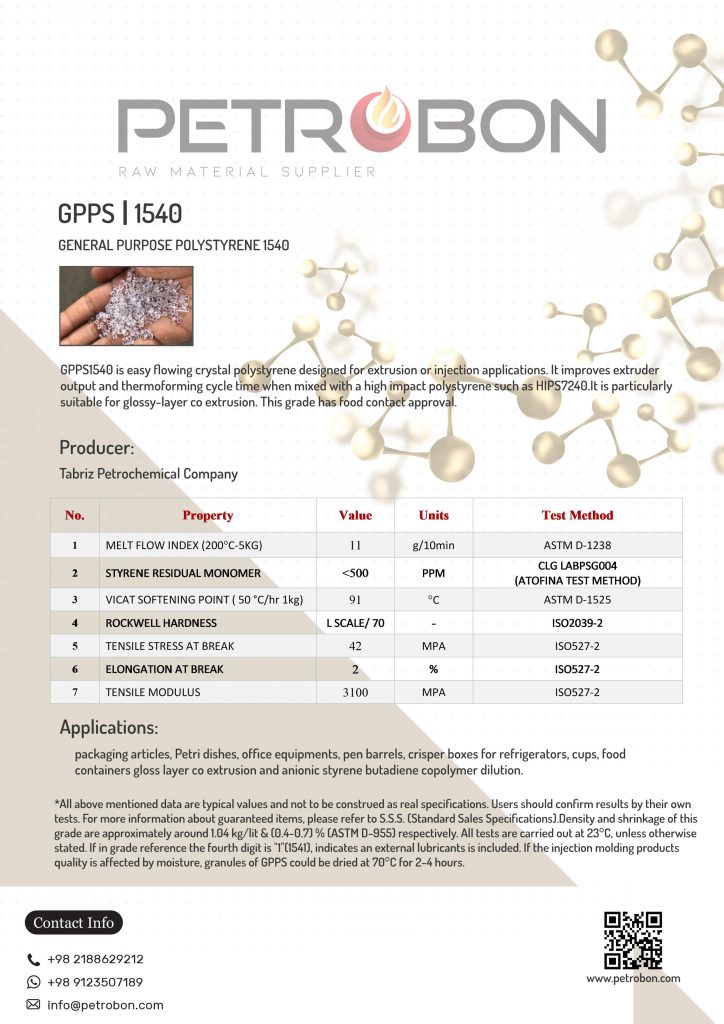

Additionally, GPPS Tabriz 1540 is suitable for food contact applications, provided that “Non-Food Contact” is not specified on the packaging. This grade has a Vicat softening point of 89.5 (120°C,1 kg), a flexural modulus of 3000 (Mpa), and an MFI of 11 (200°C & 5 kg). 1540 is supplied in pellet form and Tabriz Petrochemical Company produces this grade under the HS code 39031910.

- Excellent fluidity

It offers outstanding fluidity, allowing for smooth and efficient processing in extrusion and injection molding. This property helps in achieving uniform product quality and reduces production complexities. It leads to improved manufacturing performance.

- High softening point

It has a higher softening point compared to other grades, such as GPPS 1810/1811. This increased thermal resistance makes it suitable for applications requiring durability under higher temperatures. It ensures stability and performance in demanding environments.

- Ideal for glossy-layer co-extrusion

It excels in glossy-layer co-extrusion, providing a high-quality, smooth finish. Its fluid properties facilitate the creation of aesthetically pleasing and durable glossy surfaces. It enhances the visual appeal and functionality of the final product.

General Purpose Polystyrene Injection or Extrusion 1540 is a versatile material used across various applications due to its excellent fluidity and high softening point. In extrusion processes, it is ideal for impact dilution and glossy-layer co-extrusion. It is commonly utilized to create visually appealing and durable packaging products. It is also used in combination with anionic styrene-butadiene copolymer for enhanced performance.

For injection molding, GPPS 1540 is widely utilized in manufacturing packaging articles, and medical applications like Petri dishes, office equipment, pen barrels, crisper boxes for refrigerators, and cups. That showcases its adaptability and reliability in diverse product categories.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for Tabriz 1540 may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for PPS 1540. Please contact us to inquire about the daily prices. You can also find the price changes of this material in the chart provided in this section.

Product analysis:

Tabriz CO. Polystyrene GPPS 1540

You can see the technical specifications of General Purpose Polystyrene 1540 | GPPS 1540 in the following datasheet.