Product analysis:

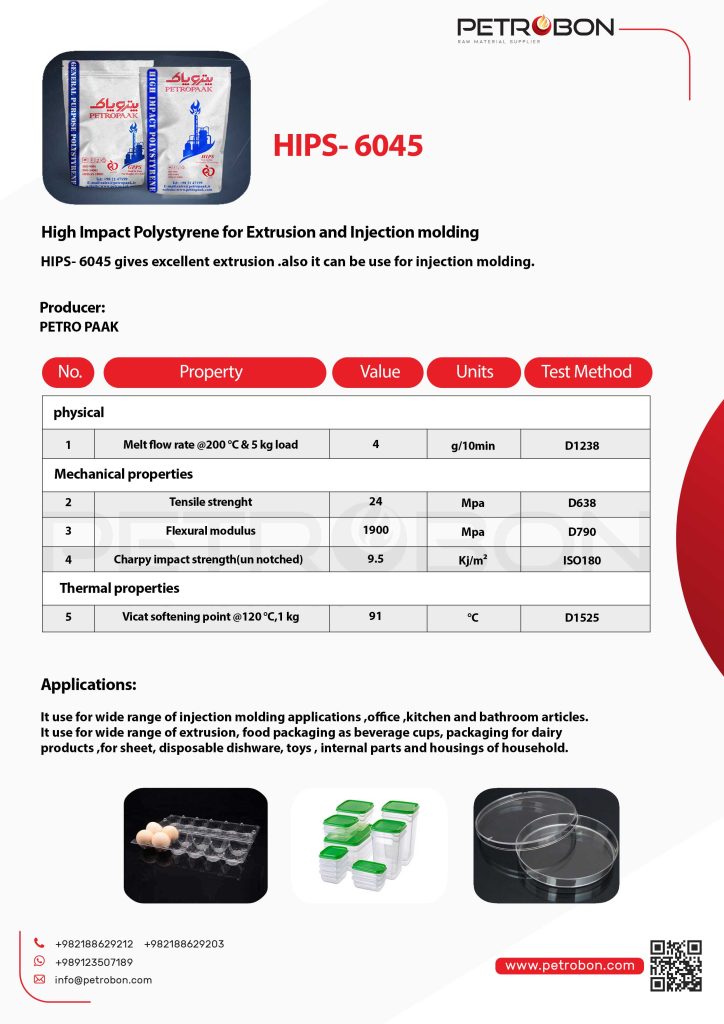

HIPS 6045 is a versatile grade of High Impact Polystyrene (HIPS) that excels in both extrusion and injection molding applications. It is designed to deliver superior performance in various manufacturing processes. It features a Vicat softening point of 91°C (measured at 120°C with a 1 kg load), making it suitable for applications requiring moderate heat resistance. With a flexural modulus of 1900 MPa. HIPS 6045 provides robust structural integrity and stiffness, ensuring durability in the final product.

Additionally, it has a Melt Flow Index (MFI) of 4 (at 200°C with a 5 kg load), indicating good flow properties for easy processing. These characteristics make HIPS-6045 an ideal choice for a wide range of industrial applications. This material is supplied in pellet form by Petro Paak Petrochemical Company under the HS code 39031990.

- Excellent extrusion

HIPS 6045 excels in extrusion processes, enabling the efficient production of consistent and high-quality products. Its properties allow for smooth processing, making it ideal for large-scale manufacturing where uniformity and precision are critical.

- Moderate heat resistance

This attribute ensures that products made from 6045 can withstand typical operational temperatures without deforming. That makes it suitable for applications where moderate thermal exposure is expected.

- Strong stiffness

With a flexural modulus of 1900 MPa, HIPS 6045 offers strong structural integrity and stiffness. This ensures that the final products are durable, maintaining their shape and strength under stress. It is essential for items requiring long-term reliability.

- Good flowability

HIPS 6045 has a Melt Flow Index (MFI) of 4, indicating good flowability. This characteristic allows the material to be easily processed in injection molding and extrusion. That maintains the necessary viscosity to produce detailed and complex shapes without compromising structural properties.

The material designated as 6045 is highly versatile, finding use in a broad range of applications. It is extensively employed in injection molding to produce office products, kitchen and bathroom articles, and other everyday items. In extrusion processes, 6045 is used to create food packaging, such as beverage cups and dairy product containers, as well as sheets for various packaging needs. Additionally, it is a popular choice for manufacturing disposable dishware, toys, and the internal parts and housings of household products. That makes it an essential material across multiple industries.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for High Impact Polystyrene Injection 6045 may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for High Impact Polystyrene Extrusion 6045 Please contact us to inquire about the daily prices. You can also find the price changes of this material in the chart provided in this section.

Product analysis:

PetroPaak Petrochemical HIPS 6045

You can see the technical specifications of HIPS 6045 | HIPS 6045 in the following datasheet.