Product analysis:

PVC S57 is a high-quality, free-flowing vinyl chloride homopolymer resin with a low molecular weight, produced through suspension polymerization. This grade of PVC, with a K value of 56.1-57.8, exhibits low porosity and very high bulk density, making it ideal for rigid applications and high machine throughput. With a viscosity range of 0.665-0.72 and a bulk density between 0.5-0.62, PVC S57 is well-suited for use as an additive polymer in specific applications. Known for its thermoplastic properties, it contains approximately 57% chlorine by weight and is widely used in various forming methods. It is supplied in powder form and is produced by Abadan and Ghadir Petrochemical Company under HS code 39041090. .

- Low melt viscosity

PVC S57’s low melt viscosity ensures smooth flow during processing, making it easier to mold into complex shapes with precision. This attribute is crucial for high-throughput applications like injection molding, where consistent flow leads to higher efficiency and reduced material waste.

- Excellent physical and mechanical properties

PVC S57 offers outstanding physical and mechanical properties, including high strength, rigidity, and durability. These characteristics make it suitable for demanding applications that require long-lasting performance and resistance to wear and tear

- Chemical resistance

PVC S57 exhibits strong resistance to chemicals, ensuring that products made from it can withstand exposure to harsh substances without degrading. This makes it ideal for use in environments where chemical exposure is common.

- Affordability

PVC S57 is a cost-effective material, offering high performance at a relatively low price. Its affordability makes it an attractive option for manufacturers looking to produce durable, high-quality products while keeping production costs manageable.

- Versatility in forming processes

PVC S57 is highly versatile and compatible with various forming processes such as injection molding, sheet extrusion, and calendaring. This flexibility allows it to be used in a wide range of applications, from rigid films and sheets to flexible sections and hoses.

PVC S57 is a versatile resin extensively used across various industries due to its excellent properties. In injection molding, it is ideal for producing rigid PVC parts and pipe fittings, where its high bulk density and low porosity are particularly beneficial. For sheet extrusion, PVC S57 is utilized in the manufacturing of rigid films and both compact and foamed rigid sheets.

In calendaring processes, this grade is employed for creating rigid films and sheets. Additionally, it is used in the extrusion of flexible sections and hoses. PVC S57 is commonly applied in electronic and electrical equipment, special packaging, and most notably, in the production of PVC fittings, where its characteristics ensure durability and precision.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for PVCS 57 may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for Suspension-Poly Vinyl Chloride 57 Please contact us to inquire about the daily prices. You can also find price changes of this material in the chart provided in this section.

Product analysis:

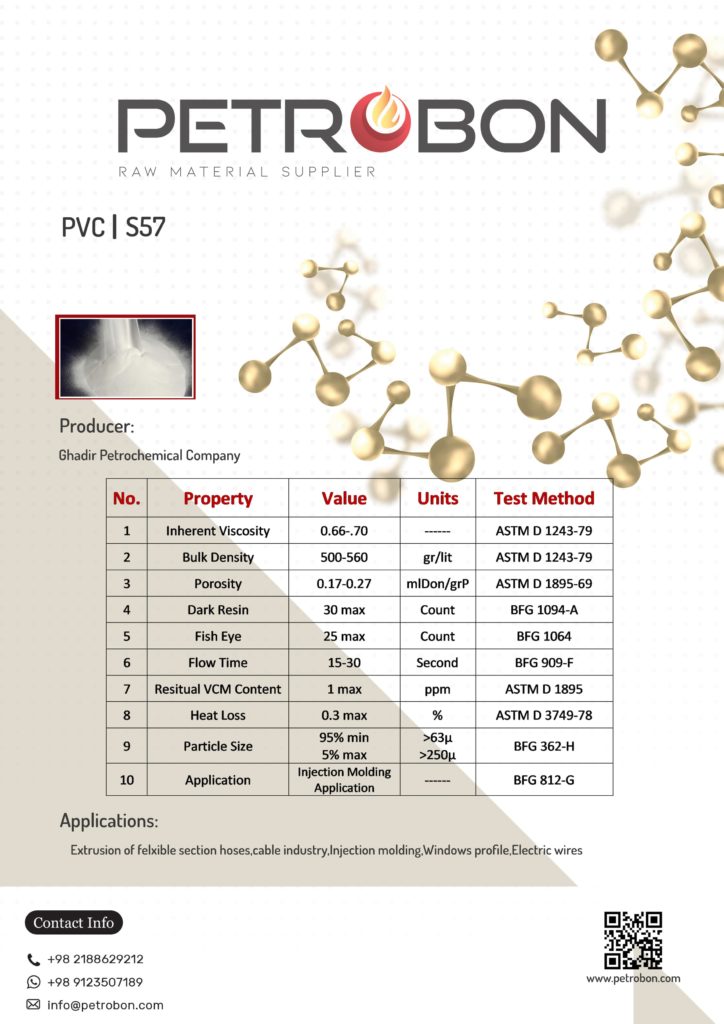

Ghadir petrochemical PVC S57

You can see the technical specifications of Polyvinyl chloride suspension 57 | PVC 57 in the following datasheet.

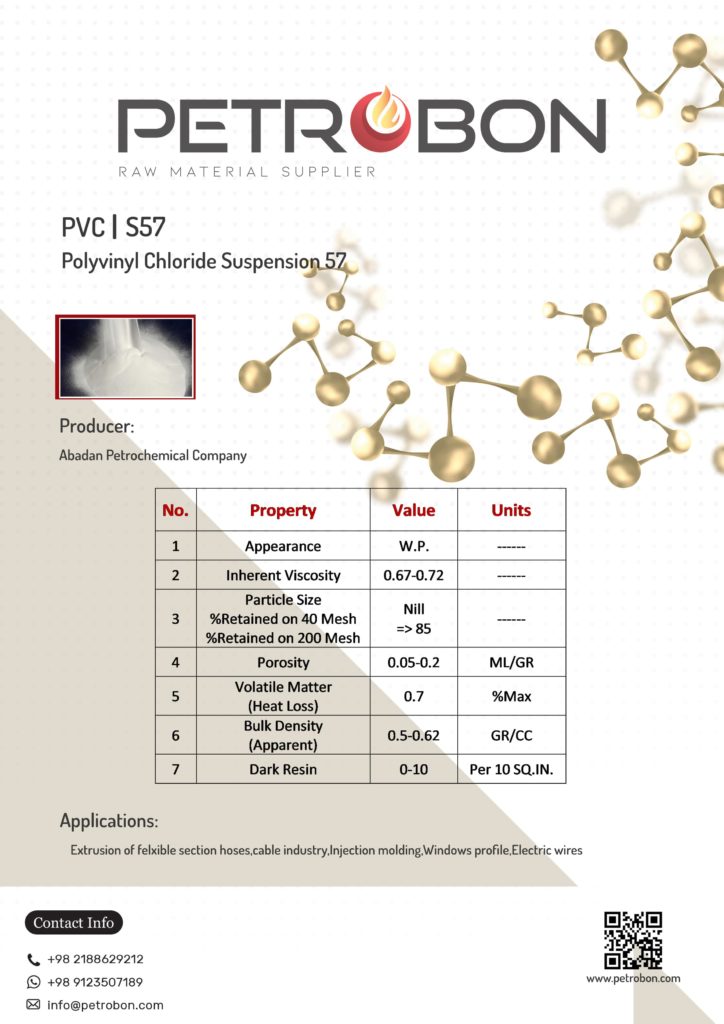

Abadan petrochemical PVC S57

You can see the technical specifications of Polyvinyl chloride suspension 57 | PVC 57 in the following datasheet.