Product analysis:

CRP100 black is a high molecular weight, high-density polyethylene (HDPE), also known as SABIC-f10750, processed through pipe extrusion. This copolymer, classified as PE 100B, provides at least 50 years of durability under appropriate pressure and temperature conditions. It has a density of 0.952 g/cm³ and a high load melt flow index (MFI) of 0.22 (190 °C/5 Kg). It is available in the form of black granules (pellets) and contains carbon black content as additives. With HS code 39012000, ARM CRP 100 black is produced by Jam, Amir Kabir, and Shazand Petrochemical Company under Basell license.

- High melt viscosity

That means materials with high melt viscosity can maintain their shape during processing when heated at the melted point. They are less likely to sag or deform during production, which helps create more consistent and durable products.

- Great ESCR

Environmental stress crack resistance represents the ability of a material to withstand physical stress, certain chemicals, or environmental conditions. This allows the production of more reliable and durable plastics which maintain their appearance and structure.

- Long-term hydrostatic strength

It refers to the ability of materials to endure internal pressure and maintain their structural integrity over a long time (a decade) without breaking or failing. This feature is totally important for materials used in pipes and pressure vessels.

- Great abrasion resistance

That means these materials can endure wear and tear caused by friction or rubbing against other surfaces. Abrasion-resistant materials maintain their surface quality and appearance over time even when subjected to repeated mechanical action or contact with abrasive substances.

- Good chemical resistance

This feature represents the ability of a material to endure degradation or damage when exposed to various chemicals, solvents, acids, or bases. These materials can maintain their shape, appearance, and functionality in harsh chemical environments.

- High creep resistance

This feature offers dimensional stability of the materials over time under constant loads and stress, especially at elevated temperatures. Without losing their strength or shape, these materials contribute to the longevity of structures and components.

- Good heat aging resistance

That means these materials can tolerate prolonged heat exposure without significant degradation in their performance or characteristics. This polyethylene can be valuable in producing durable materials in high-temperature environments.

- Excellent organoleptic properties

It refers to the ability of this polyethylene to maintain flavor, aroma, and overall sensory experience of substances, especially foods and beverages. Plus it does not contribute any undesirable tastes, odors, or other sensory characteristics to the products they come into contact with. It also offers visually appealing appearances for the packaging while not causing discoloration or other visible changes.

- Good UV resistance

This polyethylene provides the ability to endure prolonged exposure to ultraviolet radiation without significant degradation, fading, yellowing, or other color changes. These materials can maintain their physical properties, color, and overall integrity. It also helps to preserve the mechanical features of materials, preventing them from becoming brittle or weak over time.

- Good weather resistance

Products made from this polyethylene can resist various environmental conditions such as sunlight, rain, wind, humidity, temperature fluctuations, and air pollutants without significant degradation.

CRP 100 B is developed as a general-purpose resin for use in pressure and non-pressure pipes, suitable for non-conventional pipe installation methods. It is also suitable for transporting a wide range of fluids for industrial, rural, and mining applications. It is crucial in constructing water distribution systems, oil and gas pipelines, irrigation systems, and water storage tanks.

HM CRP 100 black is widely used in industries where products are exposed to chemicals or environmental stresses, common in packaging for household cleaners, industrial chemicals, personal care products, and food packaging.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for P100B may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for f10750 black. Please contact us to inquire about the daily prices. You can also find price changes of this material in the chart provided in this section.

Product analysis:

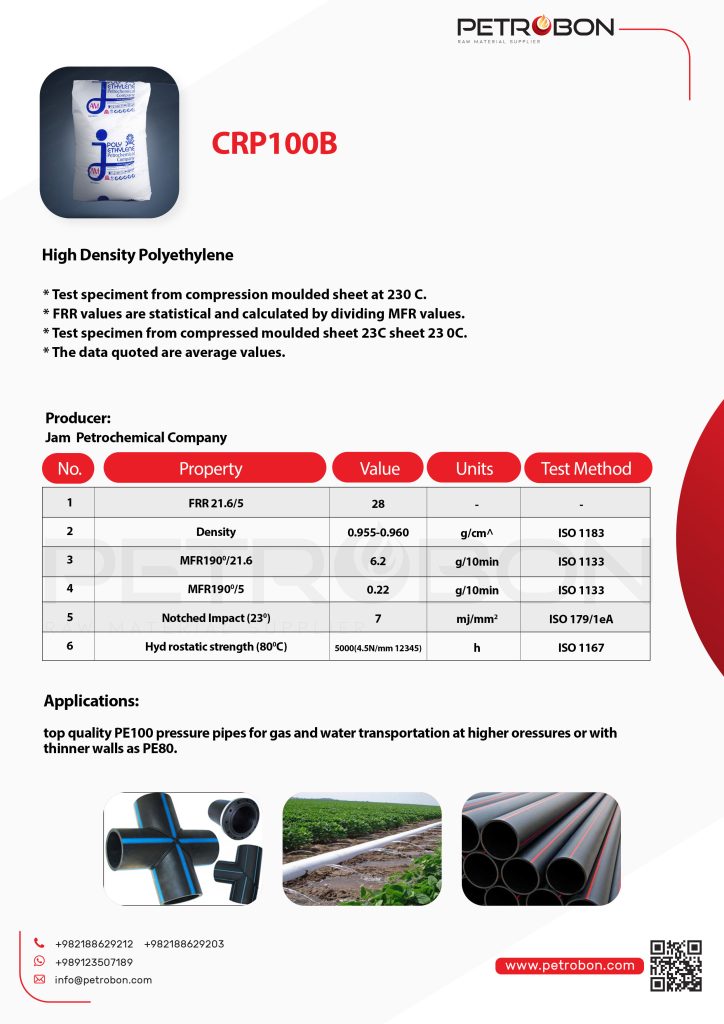

Jam Petrochemical CRP100B (PE100)

You can see the technical specifications of HDPE CRP100B | PE100 in the following datasheet.

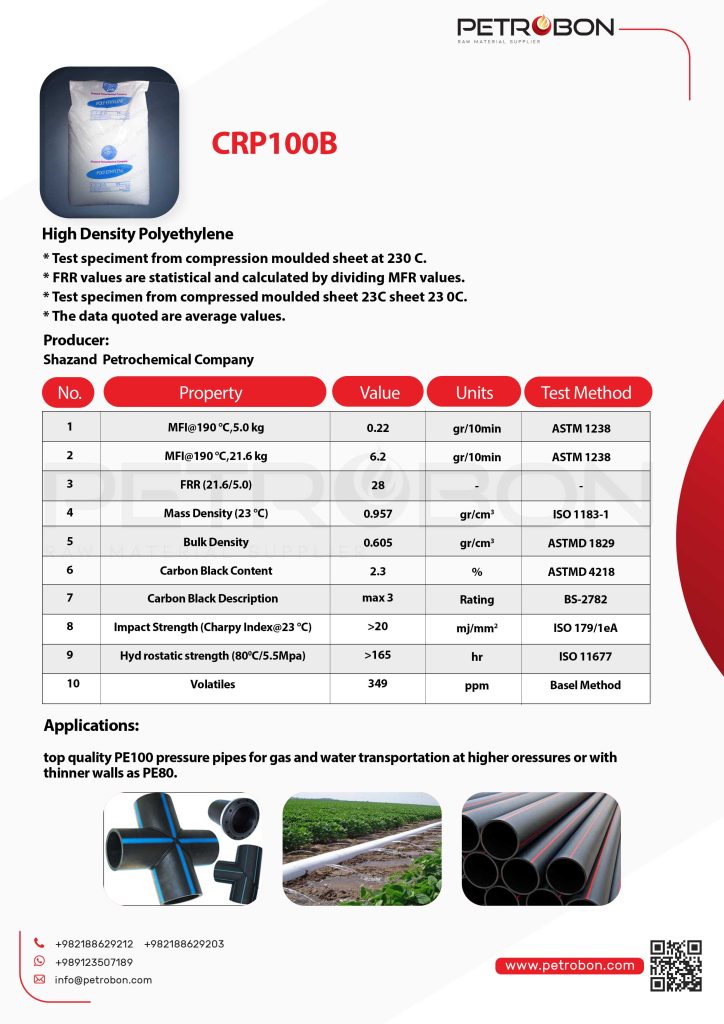

Shazand Petrochemical CRP100B (PE100)

You can see the technical specifications of HDPE CRP100B | PE100 in the following datasheet.

Amir Kabir Petrochemical CRP100B (PE100)

You can see the technical specifications of HDPE CRP100B | PE100 in the following datasheet.