Product analysis:

HD5030SA is a heavy-duty high-density polyethylene (HDPE) copolymer containing a 1-butene co-monomer. It is primarily used in plastic injection applications and is particularly recommended for manufacturing caps and closures with torque-free properties. It has a density of 0.952 g/cm³ and a melt flow index (MFI) of 2 g/10 min at 190°C under a 2.16 kg load. Supplied in granular (pellet) form, this grade contains general antioxidants and a medium content of slip agent additives. HD5030SA is manufactured by Tabriz Petrochemical Company and is approved for food contact applications.

- High ESCR

High Environmental Stress Crack Resistance (ESCR) refers to the material’s ability to resist cracking when exposed to stress and harsh chemicals. Its resistance to weathering, chemicals, and pressure ensures the durability and safety of products made from this polyethylene across various applications.

- Good processability

It shows how easily this polymer can be shaped and used to manufacture different products. This reduces necessary energy and cost while producing high-quality items quickly and efficiently. 5030 provides this feature because of its nonpolar structure and lack of reactive groups.

- Good impact resistance

It shows how easily this polymer can be shaped and used to manufacture different products. This reduces necessary energy and cost while producing high-quality items quickly and efficiently. This polymer can be easily shaped, facilitating efficient manufacturing.

- Excellent level payment

It refers to a consistent and high-quality method of distributing molten polymer across a flat surface during the manufacturing process. This property is crucial in industries such as where consistency in thickness is important such as food packaging, agricultural films, and industrial liners.

- Glossy workpiece surface

This feature refers to a smooth, shiny finish on the final product. a glossy surface can enhance transparency or specific light transmission. It also increases the visual attractiveness of the product and reduces microbial adhesion.

The properties this polyethylene provides are crucial for applications where the material might come into contact with chemicals or be subjected to stress over time. This versatile material can be used in various industries, including automotive, energy and chemicals, home and electronics, industry, and construction.

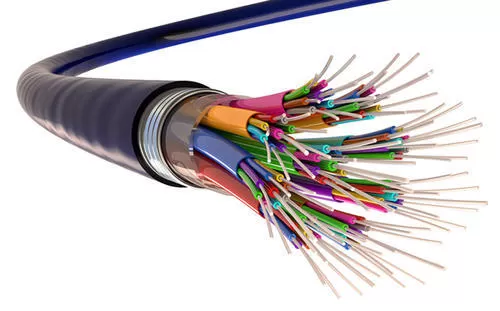

Its applications range from packaging solutions like secure caps, hatches, and injection-molded containers, to more specialized uses in cable sheathing and piping systems. The material, particularly HDPE 5030 SA, excels in producing durable plastic containers due to its high-stress crack resistance and processability. Its chemical resistance and physical robustness make it ideal for cable industry components, while its durability and environmental resistance suit it perfectly for pipes and bottle caps. This polyethylene’s diverse capabilities make it a valuable material for both consumer and industrial applications where long-lasting performance under challenging conditions is essential.”

Petrobon supplies PE 5030SA to various cities in different countries, so the logistics process and cost for HD5030 may vary. Based on your location and requirements, contact our professional team for detailed information and guidance.

Due to fluctuations in global oil prices, the cost of HDPE 5030SA is not fixed. Please contact us for the latest pricing. You can also track price changes in the chart provided in this section.

Product analysis:

Tabriz Petrochemical HD5030SA

You can see the technical specifications of HDPE 5030 | HD5030SA in the following datasheet.