Product analysis:

Low-density polyethylene LEC 1969, also known as SABIC 7019EC, Titan 801YY, Lotrene LA0710, Total LA0710, Dow 722, Sumitomo 705, and LG LB7000, is one of the LDPE injection molding grades. It is specifically developed for various applications in extrusion coating segments. As it can withstand both slow and fast line speeds, is considered a highly adaptable material in different industries. This polymer comes with a 919 (kg/m³) density and its high load melt flow index (MFI) is 6.9 (190 °C/2.16 Kg). It is available in the form of granules (pellets) and contains no additives. With an HS code of 39012000, this material is produced by Arya Sasol Petrochemical Company.

- Melt temperature at T-Die: 320°C

- Extruder temperature profile: 200-320 °C

- Outstanding melt stability

If you heat this polyethylene to its melting point it can maintain its behavior and properties. That means even at high temperature and pressure its molecular structure and viscosity are stable. It ensures reducing waste while improving efficiency to create complex or thin-walled parts.

- Excellent drawdown ability

Polyethylene with great drawdown ability has the capacity to be stretched or thinned out significantly during processing without breaking or losing its structural integrity. It allows manufacturers to produce thinner, lighter products with higher performance.

- Good edge stability

This feature represents the ability of materials to withstand the pressure during processing to maintain their edges’ shapes. It improves the material’s processability in downstream operations and enhances the final product’s appearance and performance.

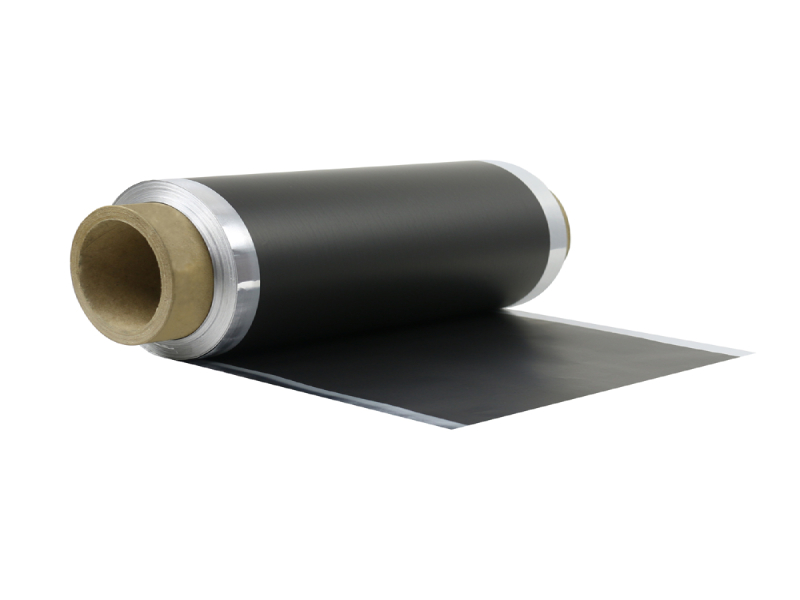

- Lightweight and very thin coating layer

This feature offers significant advantages in product design and performance. It provides a way to enhance the surface properties of materials without substantially increasing their weight or dimensions.

- High-speed production line (Up to 300 m/min)

This feature can be considered as one of the advancements in manufacturing technology. It can highly increase outputs while maintaining product quality. This high-speed production not only boosts productivity and efficiency but also reduces per-unit production costs.

- Low neck-in

A low neck-in means that the film maintains a width closer to its original die width throughout the drawing process. For manufacturers, achieving low neck-in can lead to higher productivity, as wider films can be produced without increasing die size. It reduces waste material and improves uniformity of coverage over substrates.

There are some equivalents for LEC 1969 produced by different petrochemical companies such as 7019EC, 801YY, LA0710, LA0710, 722, 705, and LB7000. PE LEC1969 and the grades mentioned above share similar applications. They represent features that are all necessary requirements for efficient and high-quality coatings. LD 1969 is known to produce very thin layers of coating on substrates due to its high adhesion performance. It is highly valued in industries where precision, consistency, and reliability are paramount.

This grade can be used for a variety of coating applications including extrusion coating and laminating, flexible packaging, paper and cardboard coating, aluminum foil coating, multi-layer packaging, food end-use contact, and direct medical use.

Petrobon is supplying this material to various cities in different countries. Therefore, the logistics process and cost for LD LEC1969 may vary. Contact our professional team for detailed information and guidance, based on your location and requirements.

There is a fact that global oil prices are variable. That means there is no stable and specific price for LDPE LEC1969. Please, contact us to inquire about the daily prices. You can also find the price changes of this material in the chart provided in this section.

Product analysis:

Arya Sasol Petrochemical 1969

You can see the technical specifications of LDPE 1969 | LDPE 1969 in the following datasheet.