Product analysis:

LDPE LFI 2125A is a low-density, round-shaped polyethylene designed for applications where ultimate down-gauging is essential. With its low molecular weight and simple structure, LFI 2125 is a lightweight polymer that offers versatility across various industries.

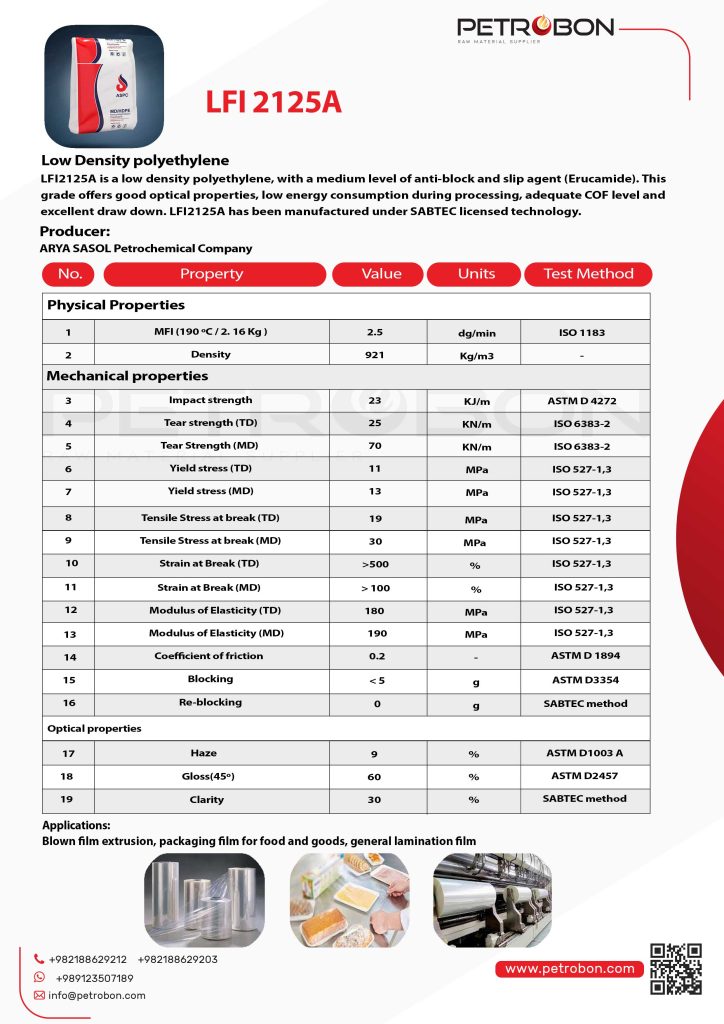

It comes with 0.921 (g/cm³) density and its high load melt flow index (MFI) is 2.5 (190 °C/2.16 Kg). It is available in the form of granules (pellets) and contains antioxidants, antiblocks, and slip agents as additives. Its Harmonized System code is 39011030. PE 2125 A is manufactured by Arya Sasol Petrochemical Company under SABTEC License.

- Extruder temperature profile: 160-180°C

- Frost line height: 5-7 times die diameter

- Blow Up Ratio: 2-3

- Recommended film thickness: 20 to 50 μm.

- Good toughness

It offers good toughness, meaning it can endure stress and impacts without easily tearing or breaking. This attribute is crucial for applications requiring durability and resistance to physical damage. It ensures that films produced with 2125A maintain their integrity in various conditions.

- High speed converting

It facilitates high-speed converting processes due to its low tendency to stick to machinery. This property allows for efficient production of films and reduces downtime, making it ideal for high-throughput applications where smooth processing is essential.

- Good optical properties

This polyethylene provides good optical properties, resulting in clear and visually appealing films. This quality is important for packaging applications where transparency and gloss are desired. Plus, it enhances product visibility and appeal.

- Low energy consumption

LD LFI 2125A contributes to low energy consumption during the processing phase. Its efficient processing characteristics help reduce the overall energy required. It makes this polyethylene a cost-effective choice and contributes to more sustainable manufacturing practices.

- Adequate COF level

This material has an adequate coefficient of friction (COF) level, ensuring optimal slip and seal performance. This attribute helps in achieving smooth handling and conversion of films. It also maintains the required friction levels to prevent unwanted sticking or slippage.

- Excellent drawdown

PE 2125A exhibits excellent drawdown capabilities, allowing the material to be stretched into thin films without losing its strength or quality. This property is particularly beneficial for producing films with fine gauges while maintaining structural integrity and performance

LDPE LFI2125A is a versatile low-density polyethylene grade highly recommended for various film applications, particularly when ultimate down-gauging is required. Its properties make it ideal for blown film extrusion processes, where it is used to produce:

- Packaging film for food and goods: LFI 2125A is well-suited for manufacturing lightweight, flexible films used in packaging both food and industrial products. Its ease of processing and lightweight nature ensure efficient and effective packaging solutions.

- General lamination films:The grade is also used in the production of general lamination films, providing a reliable, durable layer that enhances the quality and performance of laminated products.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for LDPE 2125 A may vary. Contact our professional team for detailed information and guidance, based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for Aryasasol LFI2125A. Please contact us to inquire about the daily prices. You can also find the price changes of this material in the chart provided in this section.

Product analysis:

Arya Sasol Petrochemical LFI2125A

You can see the technical specifications of LFI2125A | low density polyethylene LFI2125A film grade in the following datasheet.