Product analysis:

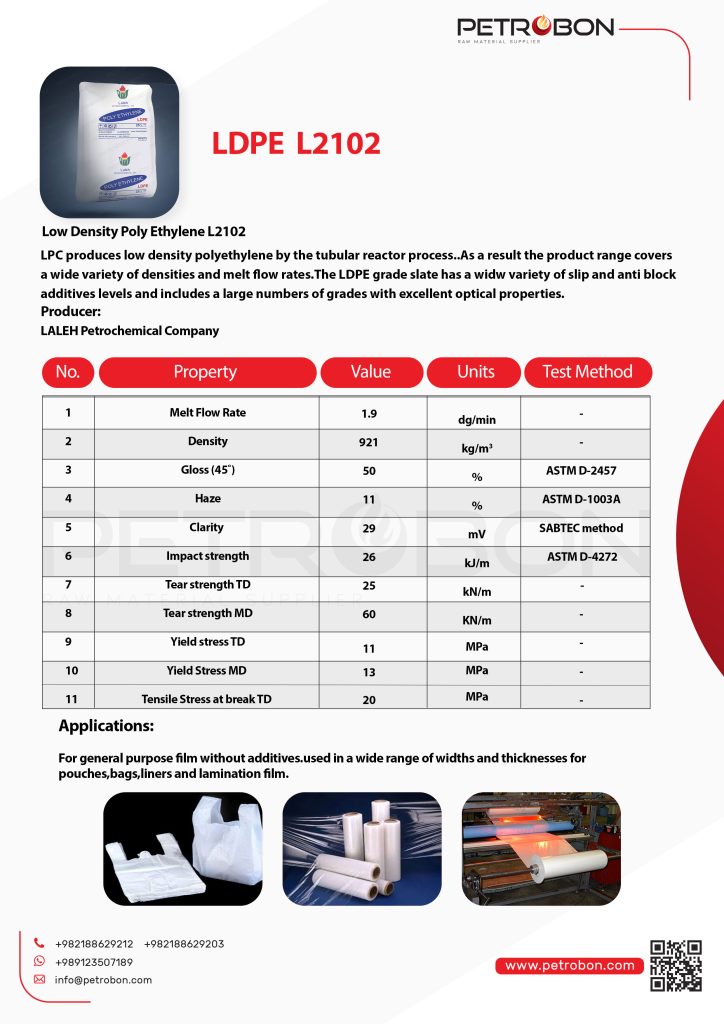

Low-density Polyethylene 2102, generally known as L2102TX00, is a versatile low-density polyethylene grade designed for blown film applications and general-purpose films. It is produced via the tubular reactor process and offers a wide range of densities and melt flow rates, making it adaptable to various manufacturing requirements. L2102T is used in films with different widths and thicknesses, and it does not contain additives, providing a base material suitable for diverse applications. The LDPE grade slate includes options with various slip and anti-block additive levels. It features a density of 0.921 (g/cm³) and MFI of 1.9 (190 °C/2.16 Kg). This grade is supplied in granular (pellet) form. PE 2102 is manufactured by Laleh Petrochemical Company under HS code 39012000.

- Good processability

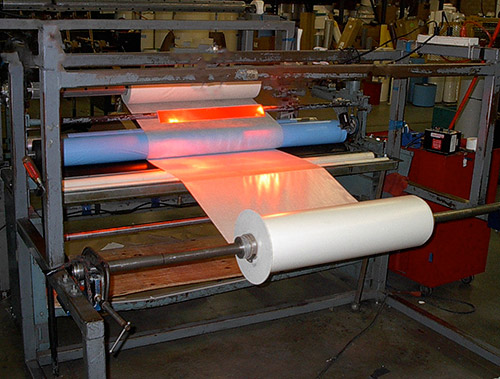

LDPE 2102 is easy to work with during film extrusion, offering smooth and consistent processing. Its adaptability to different manufacturing techniques, such as blown film extrusion, ensures efficient production with minimal defects, making it suitable for a wide range of applications.

- High impact strength at low temperature

This attribute ensures that L2102TX00 remains tough and resistant to cracking or breaking even at low temperatures. It is ideal for packaging applications where materials must withstand cold storage or harsh environmental conditions without losing integrity.

- High tensile strength

This polyethylene can withstand significant stress without breaking, providing durability and resistance to tearing. This property is essential for films that need to endure handling, transportation, and use without compromising performance.

- Excellent electrical insulating properties

LD 2102 effectively resists the flow of electricity, making it suitable for applications where electrical insulation is required. This property ensures the material can be safely used in environments where electrical conductivity must be minimized.

- Very low water absorption

This LDPE absorbs minimal moisture, maintaining its mechanical properties and preventing degradation in wet or humid environments. This makes it ideal for applications where resistance to water exposure is crucial, such as packaging and electrical insulation.

LDPE L2102TX00 is widely used in the production of pouches, bags, liners, and lamination films. It offers versatility across a broad range of widths and thicknesses. Its excellent processability and high tensile strength make it ideal for creating durable and reliable packaging solutions. The material’s adaptability and its ability to maintain integrity across different dimensions ensures that it meets the demands of various packaging applications from lightweight pouches to heavy-duty liners.

Petrobon supplies this material to various cities in different countries. Therefore, the logistics process and cost for 2102 may vary. Contact our professional team for detailed information and guidance based on your location and requirements.

Global oil prices are variable, meaning there is no stable and specific price for LDPE Blown Film 2102. Please contact us to inquire about the daily prices. You can also find price changes of this material in the chart provided in this section.

Product analysis:

Laleh Petrochemical PE LDPE2102

You can see the technical specifications of PE LDPE2102 | PE LDPE2102 in the following datasheet.